Product Introduction

Electrostatic precipitators use electrostatic forces to capture fine particles as small as 0.01µm with a high efficiency of 95-98%. This device charges particles through Corona Discharge, causing them to adhere to the surface of the collection cell. Captured particles, when they lose their charge, can be easily removed by water, vibration, or gravity.

Key Features

-

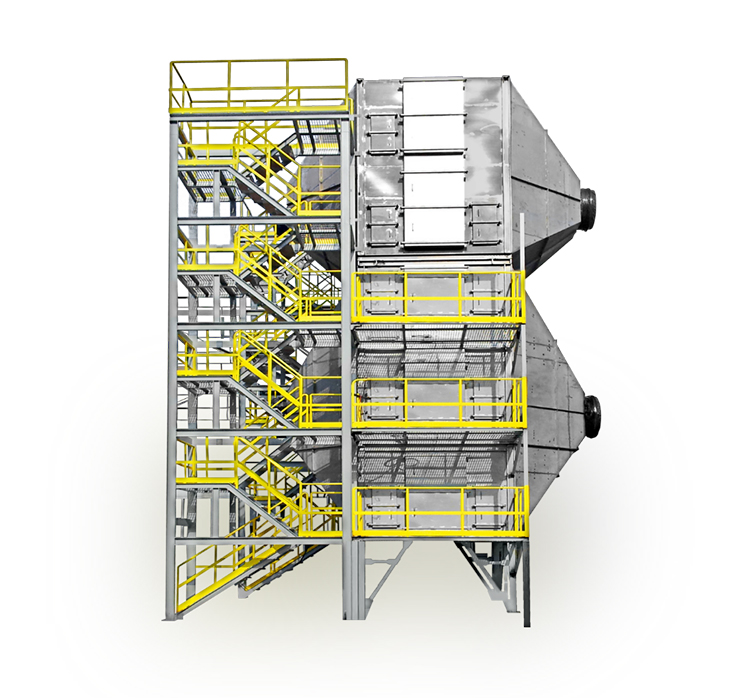

Electrostatic Precipitator

- Uses electrostatic forces to attach pollutant particles to the collection cell for filtration, achieving high collection efficiency by removing particles as small as 0.01µm with an efficiency of 95-98%.

- Since it uses electrostatic forces, it cannot be applied to particulate matter that is an insulator or conductor.

- Can operate continuously even under substantial dust loads and can handle high temperatures around 500℃.

- Handles large capacities approximately 1,400-56,000CMM at a dry 10mmAq and wet 20mmAq low pressure loss, which results in relatively low power costs.

Key Design Factors

-

- The higher the dust collection efficiency, the higher the pressure loss, which increases power costs, so airflow and inflow speed are considered in the design.

- As the efficiency of the precipitator is lower for fine particles, it is essential to understand the size and characteristics of the particulate matter to be treated.

Applications

-

- Processes generating particulate matter, such as milling, grinding, textiles, kettles, melting, reverberatory furnaces, rotary furnaces, minerals, wood, cement, plastics, food, feed, grain, milling, fertilizers, etc.

- Prefiltration devices such as fabric filters.