Product Introduction

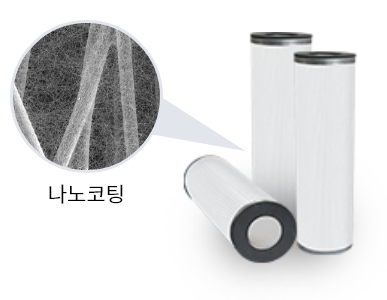

As an ascending air flow type dust collector, it removes fine particles of dust gas with the same structure and principle as the traditional filter dust collector (bag filter). Instead of a filter cloth, it is equipped with a cartridge type Ultra Nano Filter.

The Ultra Nano Filter can remove 0.3㎛ particles with 99.1% efficiency, has low pressure loss, and due to the surface treatment type filter, it experiences less clogging and has an excellent dust removal effect by the Air Pulse Jet, which prolongs its lifespan, thereby reducing the cost of filter replacement.

Due to the characteristics of the filter, when treating the same volume of dust gas, it can be designed with a faster filtration rate than traditional filter dust collectors while maintaining the same performance, allowing a significant reduction in the volume of the dust collector, thereby saving on production costs and installation space.

Key Features

-

Cartridge filter type dust collector

- Designed with a filtration speed 1.5~3 times faster than traditional filter dust collectors, resulting in a smaller volume of the dust collector, less installation space, and reduced production costs.

- Effectively handles high concentrations of dust and has a high dust collection efficiency for fine particles.

- The rate of pressure loss increase is gradual, allowing stable operation over long periods.

-

Dust collector equipped with an Ultra Nano Filter developed through proprietary patented technology

- An Ultra Nano Filter coated with Nano-Fiber on the filter surface is installed.

- The filtration efficiency (99.1%@0.3μm) is very high, effectively removing fine dust and sweepings.

- The lifespan is about twice that of filters made from common Polyester material.

- Developed and produced using our patented technology, making it more affordable than imported filters.

- General P&E Filter: Average lifespan less than 2 years

- Membrane Filter: Average lifespan less than 3 years

- Ultra Nano Filter: Average lifespan less than 4 years

Key Design Factors

-

- The sizing of the dust collector or its grading is determined by the ratio of air flow to filter area, known as filtration speed.

- Considering the temperature of the dust gas and the characteristics of the pollutants, the filtration speed is designed to not exceed 3m/min, usually around 1~2m/min.

Applications

-

- Facilities emitting particulate matter such as minerals, wood, cement, chemicals, pharmaceuticals, medicines, plastics, food, feed, grain, milling, and fertilizers

- Facilities subject to air pollution emission licensing or permitting

- Workplaces required to submit a Hazardous Risk Prevention Plan