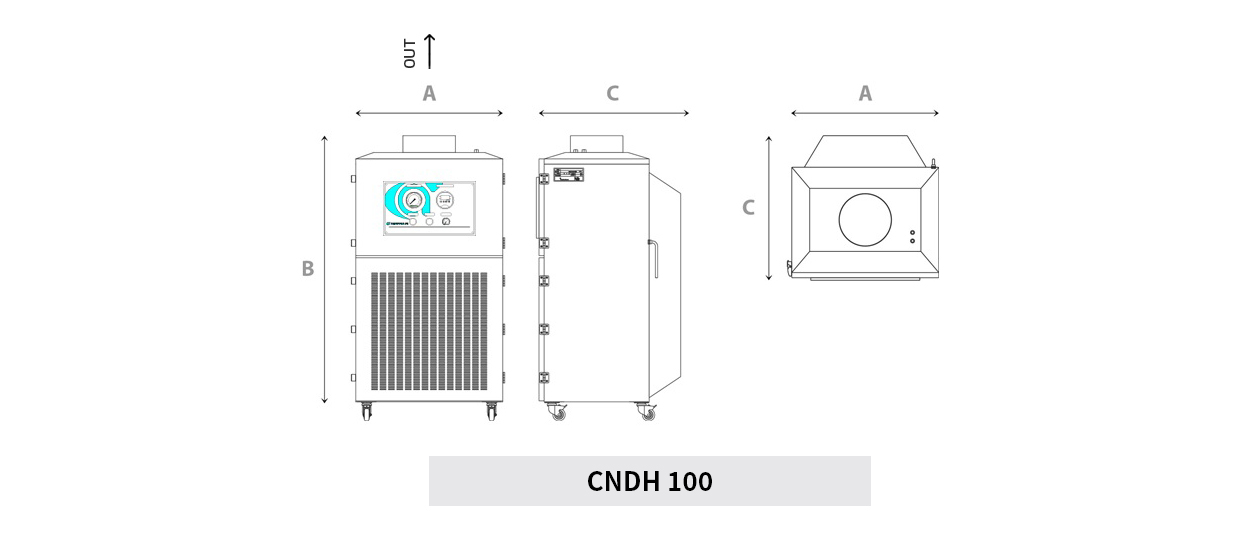

Model

CNDH 100

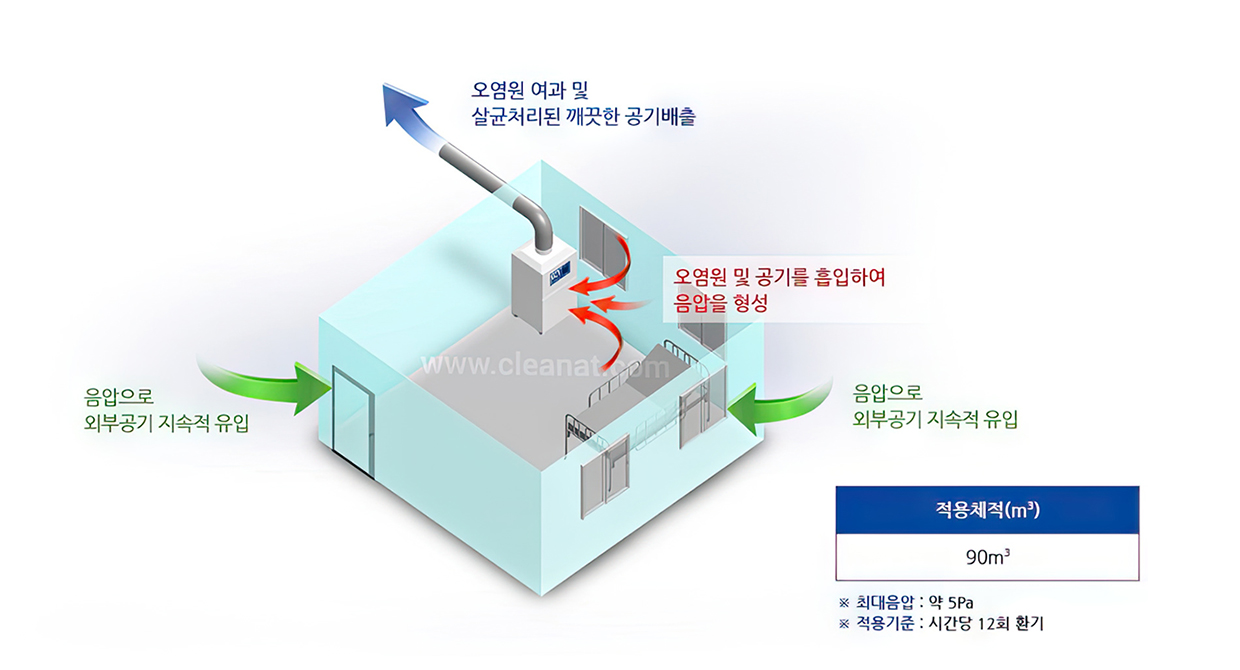

Negative Pressure Machine for Negative Pressure Hospital Rooms

- Filter Pre-filter, Hepa Filter

- Cleaning Filter Replacement Type

- Purpose Negative Pressure Formation in the Isolation Room

Product Introduction

As a hospital-grade negative pressure machine, it is used to create negative pressure in a negative pressure isolation room to prevent contaminants, bacteria, and viruses inside from leaking outside by maintaining the pressure lower than the exterior.

Specifications and Standards

Appearance

Product Specifications

| Model Name | Air Flow (CMM) |

Static Pressure (mmAq) |

Output (Kw) |

Specifications | Applicable Volume (m3) |

||

|---|---|---|---|---|---|---|---|

| Width(A) | Length(B) | Height(C) | |||||

| CNDH 100 | 26 | 70 | 0.27 x 2EA | 700 | 675 | 1,185 | 90 |

※ The height mentioned in the table excludes the height of the wheels.

※ These specifications may change for performance improvement.

Key Features

-

Negative Pressure Machine for Isolation Rooms

- This product is a negative pressure machine for isolation rooms, which has passed the leakage test by the Korea Filter Testing Institute.

- It's a stand-type negative pressure machine suitable for hospital rooms, occupying less space and allowing air volume adjustment according to the room size.

- Designed without gaps in the filter assembly area to prevent external contamination, it also features a lock to prevent unauthorized handling of contaminated filters.

- It uses a low-noise blower, resulting in relatively low noise and power consumption.

-

Two-Stage Filter Structure

- The two-stage filter structure increases particulate removal efficiency and extends the filter's life.

- The filter is designed to be filtered in the order of ① pre-filter ② HEPA filter to maximize performance.

-

Stage 1: Pre-Filter

- A pre-filter is installed to extend the life of the high-performance filter mounted downstream.

- The pre-filter made of polyester material removes larger particles as the first stage of filtration.

-

Stage 2: HEPA Filter

- The HEPA filter ultimately removes the fine particles that pass through the first stage filter.

- HEPA (High Efficiency Particulate Air) filters, developed for removing harmful microorganisms and radioactive substances, can remove more than 99.97% of particles when passing 0.3µm particles once.

- The filter performance test has been completed by the Korea Filter Testing Institute.

-

German-made Analog Differential Pressure Gauge

- An analog differential pressure gauge from AFRISO, a globally recognized measurement device manufacturer from Germany, is installed for less frequent malfunctions and precise measurements.

- The differential pressure gauge indicates when the filter is clogged, signaling when a replacement is necessary.

-

Digital Manometer

- A manometer is installed to display the pressure difference between the interior and exterior, allowing for the verification of negative pressure formation numerically.

Options (Optional)

-

Flexible Conduit for Wires

- Wires are covered with flexible conduits to prevent fire caused by insulation damage.

Precautions

-

- This equipment is not suitable for uses other than negative pressure isolation rooms.