Product Introduction

As a dust collector that removes ultrafine particulate matter, it can remove more than 99.97% of particles of 0.3μm, making it suitable for use in cleanrooms (CLASS 1~1,000), ultra-LSI manufacturing processes, and semiconductor device manufacturing processes.

Specifications and Standards

Appearance

Product Specifications

| Model | Air Volume (CMM) |

Static Pressure (mmAq) |

Output (Kw) |

Dimensions | Dust Bin (ℓ) |

|||

|---|---|---|---|---|---|---|---|---|

| Width(A) | Depth(B) | Height(C) | Inlet(D) | |||||

| CDFN-200 | 25 | 230 | 1.5 | 670 | 650 | 1520 | Ø150 | 22 |

| CDFN-300 | 40 | 230 | 2.2 | 800 | 800 | 1550 | Ø200 | 34 |

| CDFN-500 | 60 | 230 | 3.7 | 800 | 800 | 1770 | Ø250 | 34 |

| CDFN-750 | 80 | 250 | 5.5 | 1550 | 800 | 1790 | Ø300 | 86 |

| CDFN-1000 | 100 | 250 | 7.5 | 1550 | 800 | 2100 | Ø350 | 86 |

※ These specifications are subject to change for performance improvement.

Key Features

-

Three-stage Filter Structure

- The three-stage filter structure enhances the removal efficiency of particles and extends the life of the filter.

- Filters are designed to be filtered in the order of ①Pre filter ②Medium filter ③HEPA filter to maximize performance.

-

Stage 1: Pre Filter

- A pre filter is installed to extend the life of the high-performance filters mounted downstream.

- The polyester material pre filter removes larger particles as a first step.

-

Stage 2: Medium Filter

- It removes fine particles that were not filtered by the primary pre filter.

- The medium filter can select filtering efficiency from 65% to 95% depending on the media choice, accommodating a variety of filtering needs with medium to high performance.

-

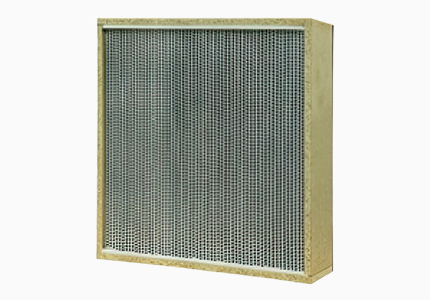

Stage 3: HEPA Filter

- The HEPA filter finally removes particles that have passed through the first and second stage filters.

- The HEPA (High Efficiency Particulate Air) filter, developed to remove harmful microorganisms and radioactive substances, can remove more than 99.97% of 0.3μm particles in a single pass.

-

German Analog Differential Pressure Gauge

- Equipped with an analog differential pressure gauge from AFRISO, a globally renowned German measuring instrument manufacturer, offering less malfunction and precise measurement.

- The pressure gauge indicates the degree of filter clogging, signaling when replacement is needed.

-

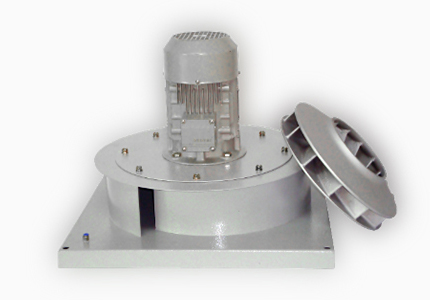

High-efficiency Turbo Fan

- Utilizes a durable high-efficiency turbo fan to deliver stable and outstanding suction power.

- The impeller is treated with ultra-precision electronic balancing to minimize vibration and noise.

Options (Selectable)

-

Combo Panel

- Changes the analog control panel to a digital controller.

- Displays the filter's differential pressure in digital figures to understand the extent of clogging.

- Includes a remote control function for controlling the dust collector in conjunction with other equipment.

- Due to the nature of digital types, durability is inferior compared to analog types.

-

Approval & Permit Configuration

- Adds stack, measurement port, safety ladder, railing, and cumulative power meter to obtain approval and permits for air pollutant emission facilities.

- For inquiries regarding approval and permit procedures, please contact us separately.

-

Control Box / Switchboard

- Configures switches, circuit breakers, and control devices in a separate steel plate box.

- Keeps electrical control devices free from contamination sources, extending their lifespan.

- Can be mounted at the desired location for use.

-

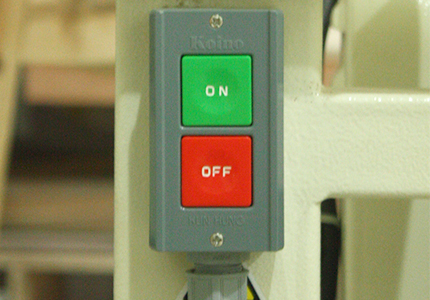

Local Switch, Contact Configuration

- Adds a local switch for powering ON/OFF.

- Can be attached at the desired location for use.

- Electrical contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wires

- Covers wires with flexible conduit to prevent fires caused by insulation damage.

-

Filter Material Change

- Can replace with filters of different materials depending on the characteristics of the contaminants.

- ULPA (Ultra-Low Penetration Air) filter: A high-efficiency filter that can remove up to 99.999% of 0.12μm particles.

- CFM filter: A glass fiber material filter effective at removing particles with moisture and oil content.

-

Customization / Custom Design

- Design modifications or new development is possible for specifications other than standard products upon request.

- We possess industry-leading design responsiveness.

-

Power Specification Changes

- Options available: 220V/ 380V/ 440V, single/three-phase, 50Hz /60Hz.

Precautions

-

- Not suitable for tasks that generate a large amount of dust.