Product Introduction

Activated carbon adsorption towers effectively remove volatile organic compounds (VOCs) and odors that are highly concentrated in organic solvents, chemical products, printed materials, paints, gases, plastics, etc. The adsorption tower can be licensed and is the most commonly used equipment for collecting volatile organic compounds.

Specifications and Standards

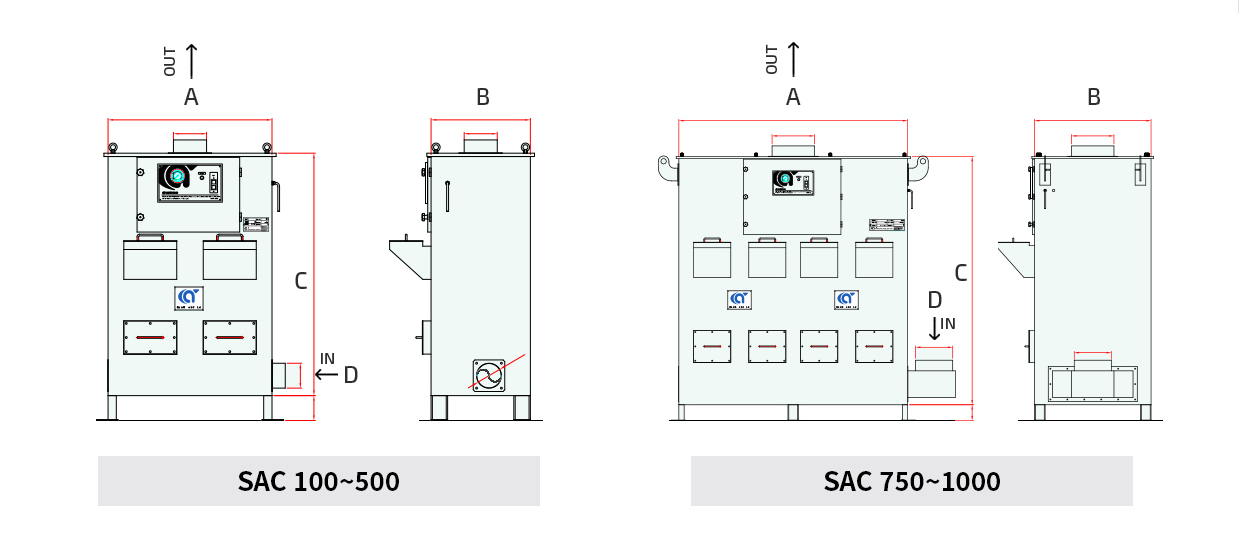

Appearance

Product Specifications

| Model Name | Air Volume (CMM) |

Static Pressure (mmAq) |

Power Output (Kw) |

Dimensions | Activated Carbon (Kg) |

|||

|---|---|---|---|---|---|---|---|---|

| Width (A) | Depth (B) | Height (C) | Inlet (D) | |||||

| SAC-100 | 12 | 200 | 0.75 | 990 | 600 | 1460 | Ø150 | 130 |

| SAC-200 | 25 | 230 | 1.5 | 1140 | 850 | 1850 | Ø200 | 275 |

| SAC-300 | 40 | 230 | 2.2 | 1200 | 1100 | 2030 | Ø250 | 440 |

| SAC-500 | 60 | 230 | 3.7 | 1390 | 1150 | 2370 | Ø300 | 635 |

| SAC-750 | 80 | 250 | 5.5 | 2160 | 1100 | 2340 | Ø350 | 1000 |

| SAC-1000 | 100 | 250 | 7.5 | 2390 | 1130 | 2370 | Ø400 | 1150 |

| SAC-1500 | 160 | 250 | 11 | 2400 | 1200 | 2410 | Ø450 | 1750 |

| SAC-2000 | 200 | 250 | 15 | 2800 | 1400 | 2640 | Ø500 | 2250 |

※ Specifications are subject to change for performance improvement.

Key Features

-

Uses a large amount of activated carbon to purify the air

- Passes volatile organic compounds (VOCs) and odors through equipment filled with activated carbon, physically and chemically absorbing and adsorbing them for removal.

- Activated carbon is made from the shell of coconut fruits, chemically and physically treated at high temperatures of 600~900°C, consisting of a carbon material with an internal surface area of about 1,200㎡ per gram.

- Due to its excellent property of adsorbing volatile organic compounds and odors through its internal surface area, activated carbon is commonly used for air purification.

-

German analog differential pressure gauge

- Equipped with an analog differential pressure gauge from AFRISO, a world-renowned German measuring instrument manufacturer, ensuring low malfunction rates and precise measurements.

- The differential pressure gauge indicates the clogging level of the filter, signaling when replacement is necessary.

-

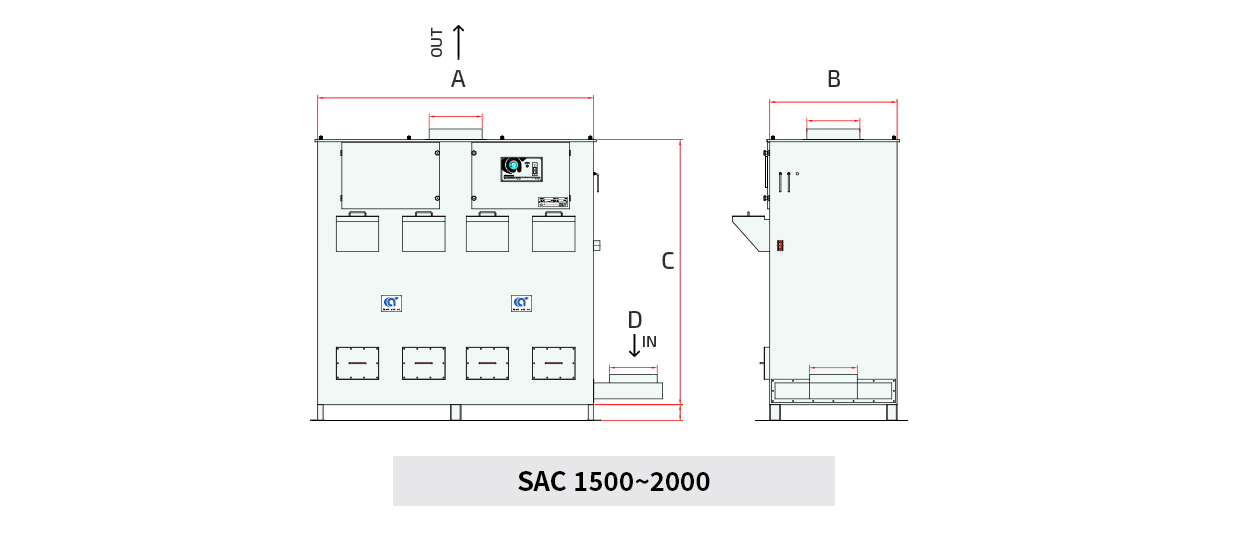

High-efficiency turbo fan

- Employs a durable, high-efficiency turbo fan that delivers stable and superior suction power.

- The impeller is treated with ultra-precise electronic balancing to minimize vibration and noise.

Options (Selectable)

-

Pretreatment device

- Adds a pretreatment device that can remove particulate matter.

-

Structures for licensing

- Includes stacks, measuring ports, safety ladders, railings, and cumulative power meters for obtaining air pollutant discharge facility licenses.

- For assistance with licensing-related tasks, please inquire separately.

-

Explosion-proof structure

- Applies explosion-proof structures, blast relief panels to minimize damage in case of an explosion, sensors to detect explosions, and firefighting devices.

-

Control box / distribution board

- Assembles switches, circuit breakers, and control devices in a separate steel plate box.

- Electrical control devices are not affected by contaminants, thereby extending their lifespan.

- Can be attached and used at the desired location.

-

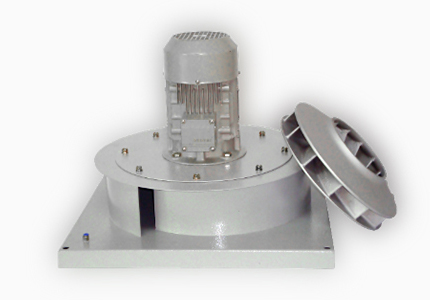

Local switch, contact configuration

- Adds a local switch for turning the power ON/OFF.

- Can be attached and used at the desired location.

- Electrical circuit contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible conduit for wires

- Covers wires with a flexible conduit to prevent fire caused by insulation damage.

-

Customization / Custom design

- Design changes or new developments to specifications other than standard products are possible upon request.

- We have the industry's highest level of design responsiveness.

-

Power specification change

- Selection is available for 220V/ 380V/ 440V, single-phase/three-phase, 50Hz /60Hz.

Precautions

-

- If a license for the air pollutant discharge facility is required, please inquire in advance.