Product Introduction

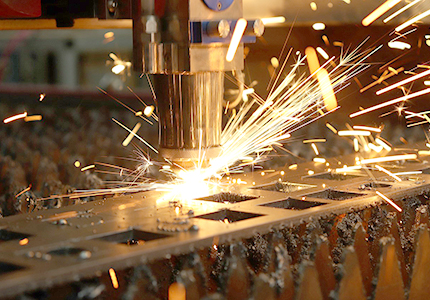

A downdraft dust collector specialized for removing fume generated in large quantities during plasma & laser processing of steel, stainless steel, etc., with an air pulse cleaning system.

Specifications and Standards

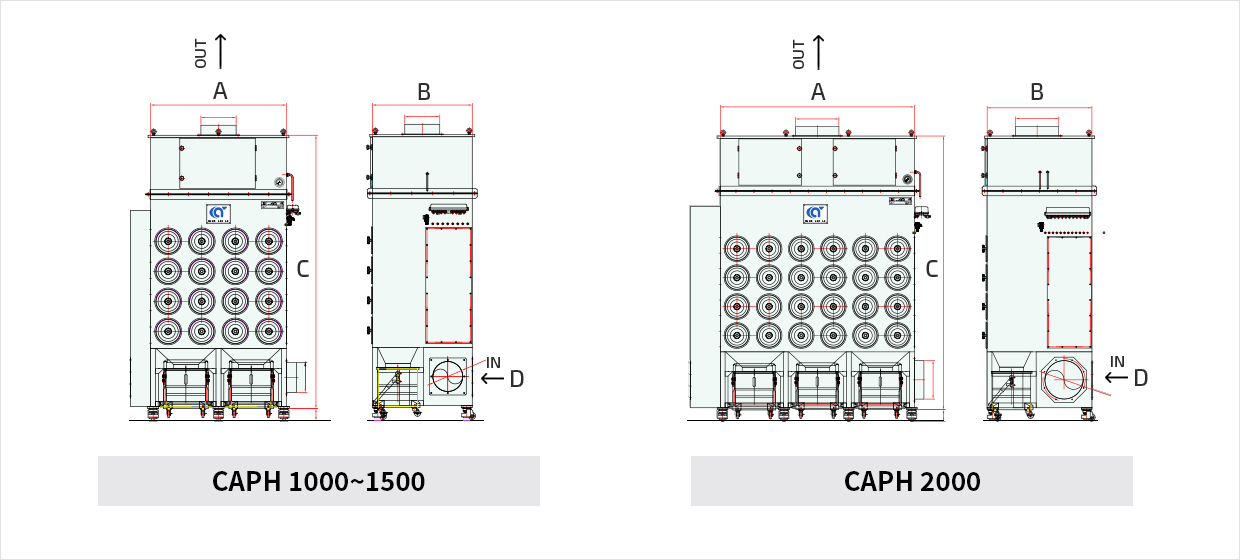

Appearance

Product Specifications

| Model Name | Air Volume (CMM) |

Static Pressure (mmAq) |

Power (Kw) |

Specifications | Filter | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Width(A) | Depth(B) | Height(C) | Inlet(D) | Q’ty | Filtration Speed | Filtration Area | ||||

| CAPH-1000 | 80 | 300 | 7.5 | 1350 | 1000 | 2710 | Ø300 | 16 | 0.83 | 96 |

| CAPH-1500 | 100 | 300 | 11 | 1350 | 1040 | 2930 | Ø350 | 16 | 1.04 | 96 |

| CAPH-2000 | 160 | 300 | 15 | 2018 | 1090 | 2820 | Ø400 | 24 | 1.11 | 144 |

※ Specifications may change for performance improvement.

Key Features

-

Dust collector specialized for plasma & laser fume removal

- Designed with a low filtration speed (0.8~1 m/min) to increase filtration efficiency for plasma & laser fume and to extend the life of the filter.

- Constructed with a fire prevention structure that extinguishes flames internally to prevent fires caused by high heat and sparks.

- Main components susceptible to contamination are externalized to reduce malfunctions.

-

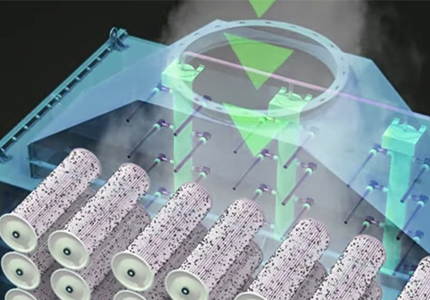

Downdraft Dust Collector

- A downdraft type of dust collector with horizontally mounted filters, where the contaminants are sucked from top to bottom.

- The downdraft structure prevents the re-entrainment of settled particles by upward airflow and enhances filter life by preventing reattachment of particles to the filter surface during air pulsing (cleaning the filter with compressed air).

-

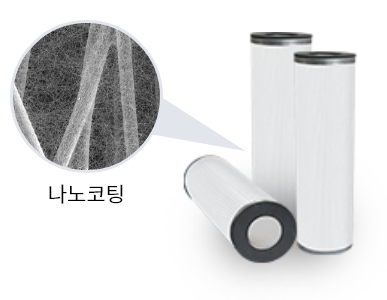

Dust collector equipped with ultra nano filters developed with proprietary patent technology

- Equipped with ultra nano filters coated with nano fibers on the filter surface.

- Very high filtration efficiency (99.1%@0.3μm) allows for effective removal of fine dust and fume.

- Approximately twice the lifespan compared to commonly used polyester material filters.

- Developed and produced with our patent technology, making it more affordable than imported filters.

- Standard P&E filter: Less than 2 years lifespan

- Membrane filter: Less than 3 years lifespan

- Ultra nano filter: Less than 4 years lifespan

-

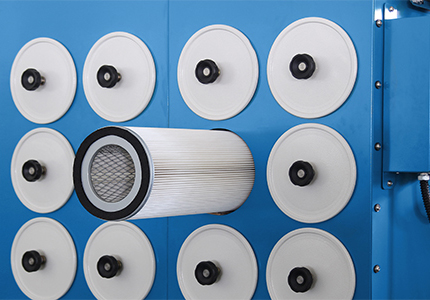

Air Pulse Jet Cleaning Method

- Cleans the filter using an air pulse device (spraying compressed air from the air tank at set intervals).

- Allows for filter cleaning even during operation of the dust collector. (Continuous operation 24/7)

- Particles dislodged during cleaning are collected in the dust bin at the bottom.

- Filters can be individually replaced without tools by simply loosening a knob, which is convenient.

-

One-Touch Detachable Dust Bin

- Designed for easy emptying of dust with a one-touch detachable dust bin.

- Features a viewing window to check the level of accumulated dust and wheels for easy mobility when emptying the dust bin.

- The increased distance between the filter and dust bin reduces the re-entrainment of particles during air pulsing, thereby extending the life of the filter.

-

German-made Analog Differential Pressure Gauge

- Equipped with an analog differential pressure gauge from AFRISO, a world-renowned German measuring device manufacturer, ensuring low malfunction rates and precise measurements.

- The differential pressure gauge indicates the clogging level of the filter to signal the replacement time.

-

Control Box / Distribution Board

- Incorporates switches, circuit breakers, and control devices in a separate sheet metal box.

- Electrical control devices are protected from contaminants, extending their lifespan.

- Can be attached at a location of your choice.

Options (Optional)

-

Local Switch, Contact Configuration

- Adds a local switch for ON/OFF power control.

- Can be attached at a desired location.

- Electrical circuit contacts can be configured to operate ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wires

- Prevents fire by covering wires with a flexible conduit to protect the insulation from damage.

-

Power Specification Change

- Options available: 220V/ 380V/ 440V, single-phase/three-phase, 50Hz/60Hz.

Precautions

-

- An air compressor is required since the filter is cleaned using compressed air.

- Please inquire separately for adhesive fume such as film cutting fume, soldering fume containing flux, and fume generated from heating silicon material in ovens.