Model

CAPU 100 ~ 2000

Air Pulse Dust Collector

- Filter Ultra Nano Filter (Cartridge Type)

- Cleaning Automatic, Air Pulsing (Air Compressor Required)

- Purpose Fine Dust and Fume Removal

Product Introduction

This is a universal air pulse dust collector that effectively removes large amounts of fine dust generated from various operations such as grinding, milling, drilling, cutting, machining, trimming, shredding, grinding, sanding, powder injection, mixing, etc., using an updraft method. This dust collector is widely used among dust collectors due to its excellent performance and the ability to be custom-made in various forms.

Specifications and Standards

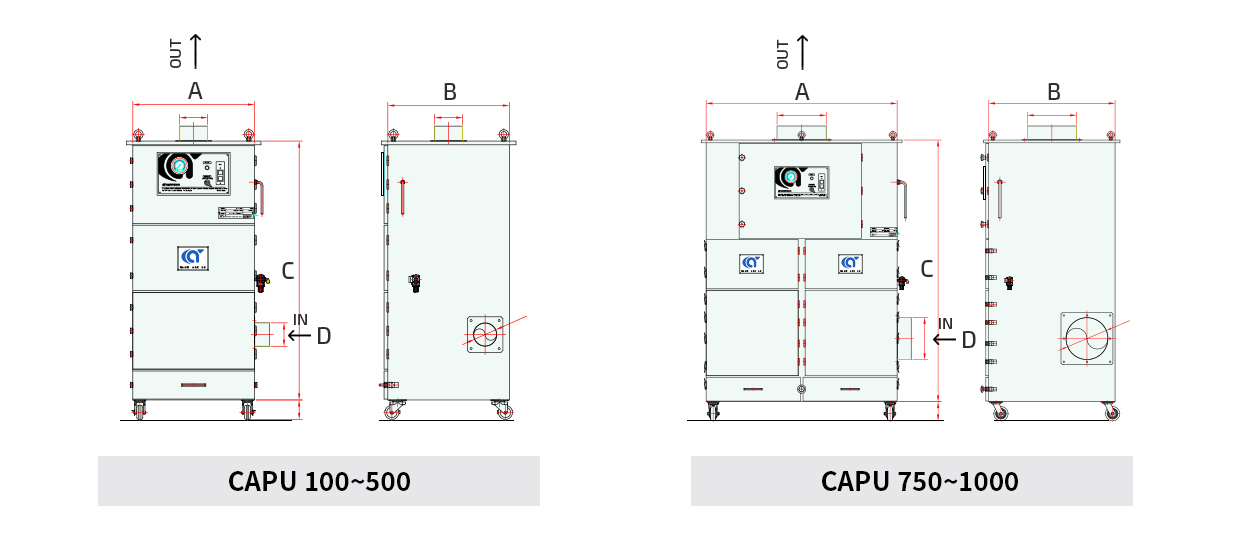

Appearance

Product Specifications

| Model Name | Air Volume (CMM) |

Static Pressure (mmAq) |

Power (Kw) |

Dimensions | Dust Bin (ℓ) |

Weight (Kg) |

|||

|---|---|---|---|---|---|---|---|---|---|

| Width(A) | Depth(B) | Height(C) | Inlet(D) | ||||||

| CAPU-100 | 12 | 200 | 0.75 | 650 | 650 | 1385 | Ø125 | 22 | 160 |

| CAPU-200 | 25 | 230 | 1.5 | 650 | 650 | 1655 | Ø150 | 22 | 178 |

| CAPU-300 | 40 | 230 | 2.2 | 770 | 770 | 1705 | Ø200 | 31 | 224 |

| CAPU-500 | 60 | 230 | 3.7 | 900 | 850 | 1775 | Ø250 | 41 | 280 |

| CAPU-750 | 80 | 250 | 5.5 | 900 | 1865 | Ø300 | 84 | 490 | |

| CAPU-1000 | 100 | 250 | 7.5 | 1800 | 900 | 1925 | Ø350 | 105 | 580 |

| CAPU-1500 | 160 | 250 | 11 | 1800 | 900 | 2145 | Ø400 | 105 | 713 |

| CAPU-2000 | 200 | 250 | 15 | 2000 | 900 | 2165 | Ø450 | 118 | 800 |

※ Specifications are subject to change for performance improvement.

Key Features

-

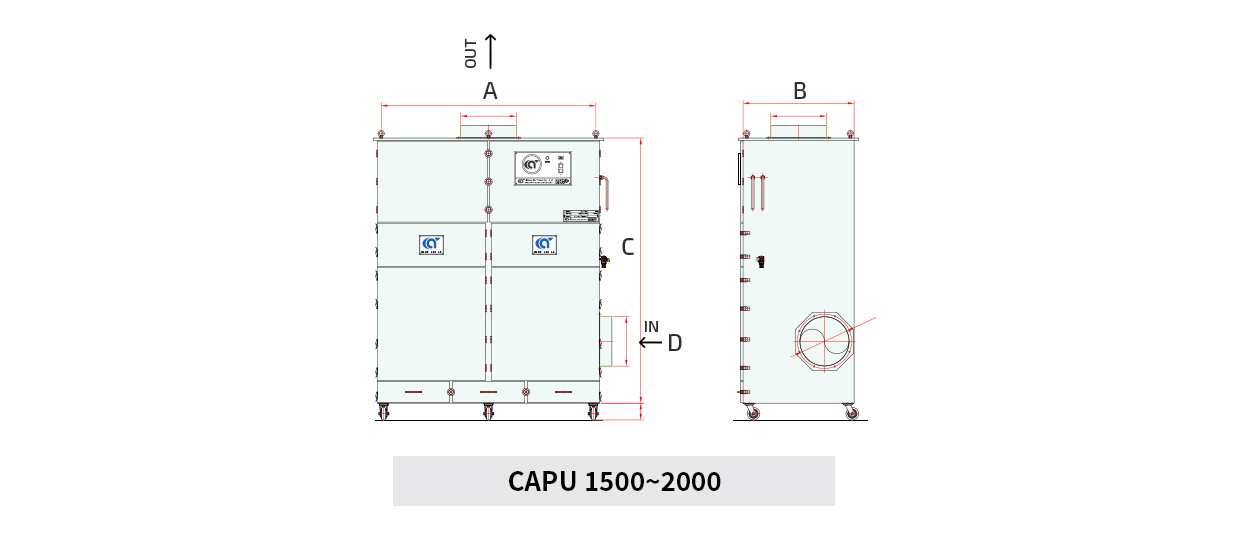

Dust collector equipped with an Ultra Nano Filter developed

with proprietary patented technology- Equipped with an ultra nano filter coated with nano-fiber on the filter surface.

- Very high filtration efficiency (99.1%@0.3μm) allows for effective removal of fine dust and fumes.

- The lifespan is about twice as long compared to commonly used polyester (Polyester) material filters.

- Developed and produced with our patented technology, making it more affordable than imported filters.

- General P&E Filter: Less than 2 years average lifespan

- Membrane Filter: Less than 3 years average lifespan

- Ultra Nano Filter: Less than 4 years average lifespan

-

Air Pulse Jet Cleaning Method

- Cleans the filter using an air pulse device (injecting compressed air from the air tank at regular intervals).

- Allows for filter cleaning even while the dust collector is operating (24-hour continuous operation possible).Equipped with a Venturi that enhances efficiency when cleaning the filter by injecting compressed air.

- Particles dislodged during cleaning are collected in the dust bin at the bottom.

-

German-made Analog Differential Pressure Gauge

- Equipped with an analog differential pressure gauge from AFRISO, a world-renowned German measuring instrument manufacturer, offering low maintenance and precise measurements.

- The differential pressure gauge indicates the degree of filter clogging, suggesting when a replacement is necessary.

-

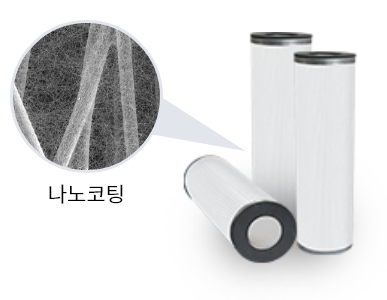

High-efficiency Turbofan

- Uses a durable, high-efficiency turbofan to provide stable and excellent suction power.

- The impeller undergoes precision electronic balancing to minimize vibration and noise.

Options (Selectable)

-

Cyclone

- Using a cyclone as a pre-treatment device can significantly reduce the amount of dust entering the dust collector, thereby extending the life of the filter.

- Removes dust using the principles of centrifugal force and gravitational settling.

- Especially effective for operations generating large and heavy particles of wood dust, metal dust, etc.

- Not suitable for fine, light particles of dust.

-

Combo Panel

- Switches from an analog control panel to a digital controller.

- Displays the filter differential pressure in digital format to assess the level of filter clogging.

- Includes a remote control feature for controlling the dust collector in conjunction with other equipment.

- The durability of digital types is lower compared to analog types.

-

CE Certification

- The CAPU series meets all the requirements of the EU Council directives related to safety, health, environmental, and consumer protection, obtaining CE certification. This certification can be applied as an option.

-

One-touch Detachable Dust Bin

- Changes from a heavy and inconvenient drawer-type dust bin to a dust bin that can be easily detached with one touch.

- Has a window to check the amount of accumulated dust and wheels for convenience in emptying the dust bin.

- The distance between the filter and dust bin is increased, reducing particle resuspension due to air pulsing and thus extending the filter's life.

-

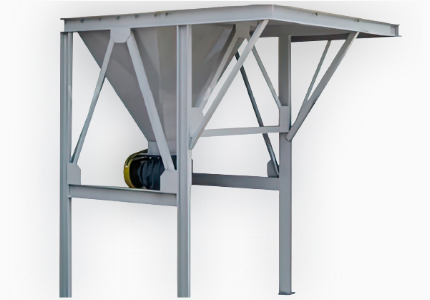

Hopper, Valve

- Changes the dust bin to a funnel-shaped structure, allowing for efficient handling of large amounts of dust.

- Dust can be emptied using either a rotary valve (automatic control) or a butterfly valve (manual control).

- The increased distance between the filter and dust bin reduces particle resuspension due to air pulsing, thus extending the filter's life.

-

Permit-required Structure

- Adds features such as stack, measuring ports, safety ladders, railings, and power meters to obtain emissions permits for air pollutants.

- For assistance with permit-related matters, please inquire separately.

-

Explosion-proof Structure

- Applies an explosion-proof structure and devices to minimize damage in the event of an explosion, including explosion relief panels, sensors, and firefighting equipment.

-

Bin Vent-type Structure

- Modifies the bottom part to a flange type for use with hoppers (Hopper) and silos (Silo).

-

Flame Arrestor

- Adds a device to extinguish flames sucked in, preventing fires.

-

Control Box / Distribution Board

- Configures switches, circuit breakers, and control devices in a separate steel plate box.

- The electrical control devices are not affected by contaminants, extending their lifespan.

- Can be attached at a desired location for use.

-

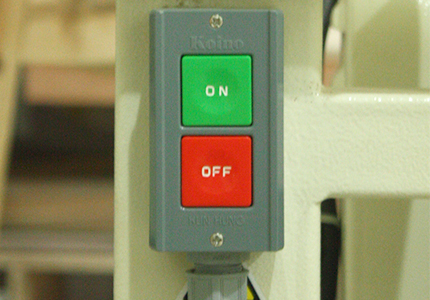

Local Switch, Contact Configuration

- Adds a local switch for ON/OFF power control.

- Can be attached at a desired location for use.

- Electrical circuit contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wiring

- Covers wiring with flexible conduit to prevent fire caused by insulation damage.

-

Filter Material Change

- Filters can be replaced with different materials depending on the characteristics of the pollutants.

- GDC-TEX Filter: A special filter coated with a membrane.

- Polyester Filter: A standard filter for dust.

-

Customization / Tailored Design

- Design changes or new developments other than standard products are possible upon request.

- Our company possesses the highest level of design responsiveness in the industry.

-

Power Specification Changes

- Options available for 220V/ 380V/ 440V, single-phase/three-phase, 50Hz/60Hz.

Precautions

-

- An air compressor is required because the filter is cleaned using compressed air.

- For dust with explosion risks such as aluminum, titanium, epoxy, please inquire separately.

- For sticky fumes such as film cutting fumes, soldering flux containing fumes, and fumes from processing silicone materials in heating furnaces, please inquire separately.

- If flames are sucked in along with pollutants, a [Flame Arrestor] must be installed.

- Not suitable for hot gases or dust containing moisture/oil mist.

- If an air pollutant discharge facility permit is required, please inquire in advance.