Product Introduction

As a total ventilation dust collector, it can reduce airborne dust in confined spaces where it is difficult to install local exhaust devices such as workshops and warehouses.

Specifications and Standards

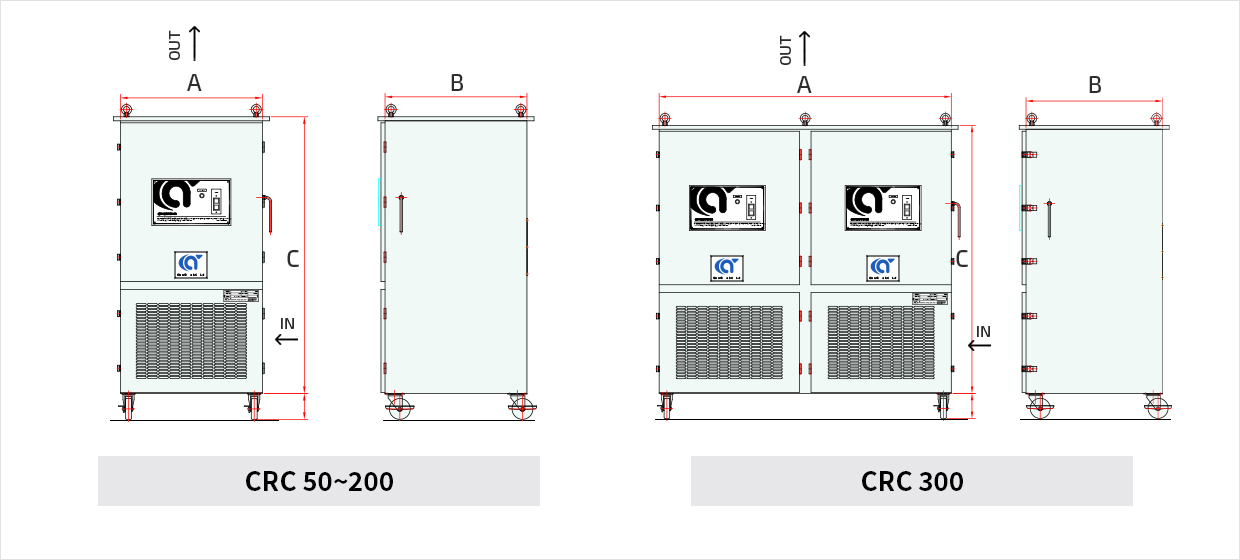

Appearance

Product Specifications

| Model Name | Air Volume (CMM) |

Static Pressure (mmAq) |

Output (Kw) |

Standards | Applicable Area (㎡) |

Weight (Kg) |

||

|---|---|---|---|---|---|---|---|---|

| Width(A) | Depth(B) | Height(C) | ||||||

| CRC-50 | 17 | 29 | 0.15 | 550 | 500 | 1050 | 33~66 | 72 |

| CRC-100 | 38 | 32 | 0.2 | 700 | 700 | 1370 | 66~122 | 160 |

| CRC-200 | 57 | 43 | 0.3 | 800 | 750 | 1630 | 122~158 | 185 |

| CRC-300 | 76 | 32 | 0.2 x 2 | 1500 | 700 | 1370 | 158~211 | 274 |

※ The applicable area is calculated based on 5~10 ventilations per hour.

Key Features

-

Total Ventilation Dust Collector

- This dust collector of total ventilation type can be used by simply connecting to a power source without the need for separate hood or piping works.

- Equipped with four heavy-duty casters for easy movement in any direction.

- It uses a low-noise sirocco fan, resulting in low noise, low power consumption, and high air volume.

-

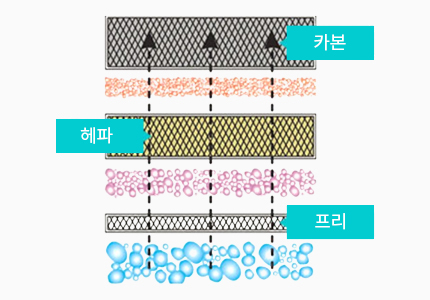

3-Stage Filter Structure

- The 3-stage filter structure enhances the removal efficiency of fine particles and extends the life of the filter.

- To maximize filter performance, it is designed to filter through in the order of ①Pre-filter ②HEPA filter ③Carbon filter.

-

Stage 1: Pre-filter

- A pre-filter is installed to extend the life of the high-performance filters installed downstream.

- The pre-filter made of polyester material primarily removes larger particles.

-

Stage 2: HEPA Filter

- The HEPA filter secondarily removes fine particles not filtered by the pre-filter.

- HEPA (High Efficiency Particulate Air) filters, developed to remove harmful microorganisms and radioactive substances, can remove over 99.97% of particles of 0.3µm in size on a single pass.

-

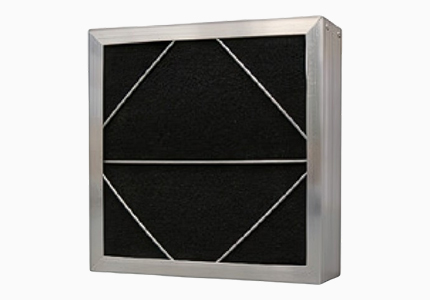

Stage 3: Carbon Filter

- The carbon filter, made by mixing polyester fiber and activated carbon, removes volatile organic compounds (VOCs) and odors that have passed through the first and second filters.

Options (Optional)

-

Combo Panel

- Changes the analog control panel to a digital controller.

- Displays the differential pressure of the filter in digital figures, allowing for an understanding of the filter's blockage level.

- Features a remote control function for control in conjunction with other equipment.

- Due to its digital nature, durability is lower compared to analog types.

-

Control Box / Distribution Board

- Configures switches, circuit breakers, and control devices in a separate steel box.

- Keeps electrical control devices from being affected by contaminants, thus extending their lifespan.

- Can be attached at a desired location for use.

-

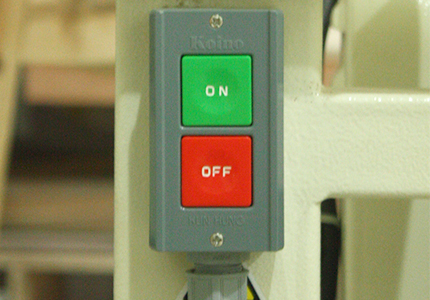

Local Switch, Contact Configuration

- Adds a local switch for turning the power ON/OFF.

- Can be attached at a desired location for use.

- Electrical contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wiring

- Applies a flexible conduit to the wiring to prevent fires caused by insulation damage.

-

Filter Material Change

- Depending on the characteristics of the contaminant, it is possible to replace with a filter of a different material.

- Medium (MEDIUM) filter: Depending on the MEDIA selection, filtration efficiency between 65% to 95% can be chosen, allowing for a response to a variety of filtering needs with medium to high-performance filters.

-

Customizing / Custom Design

- Design changes or new developments to specifications other than standard products are possible upon request.

- Our company possesses industry-leading design responsiveness.

-

Power Specification Changes

- Options available: 220V/ 380V/ 440V, single-phase/three-phase, 50Hz /60Hz.

Precautions

-

- Not suitable for operations that generate large amounts of dust.