Product Introduction

This is a universal air pulse dust collector that effectively removes large amounts of fine dust generated from various operations such as grinding, milling, drilling, cutting, machining, cutting, shredding, grinding, sanding, powder injection, mixing, etc., using a downward airflow method.

Specifications

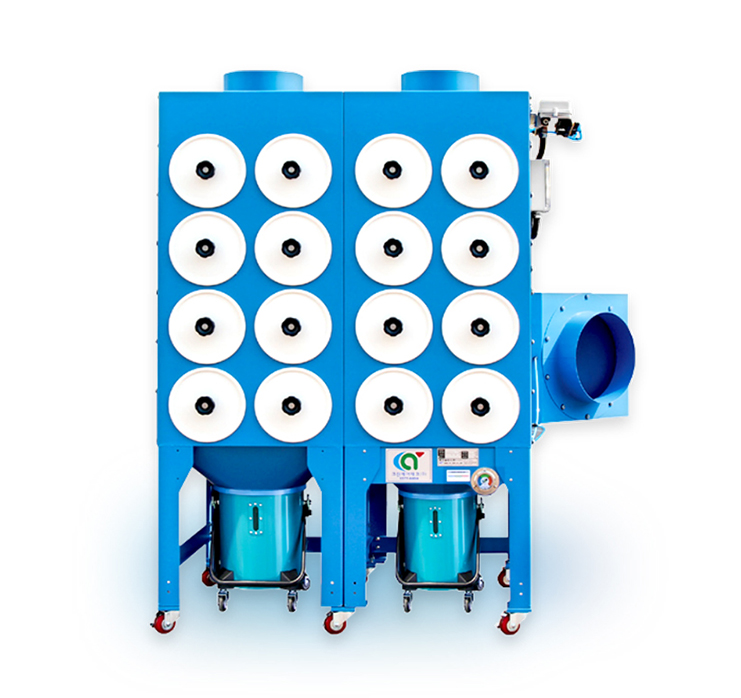

Appearance

Product Specifications

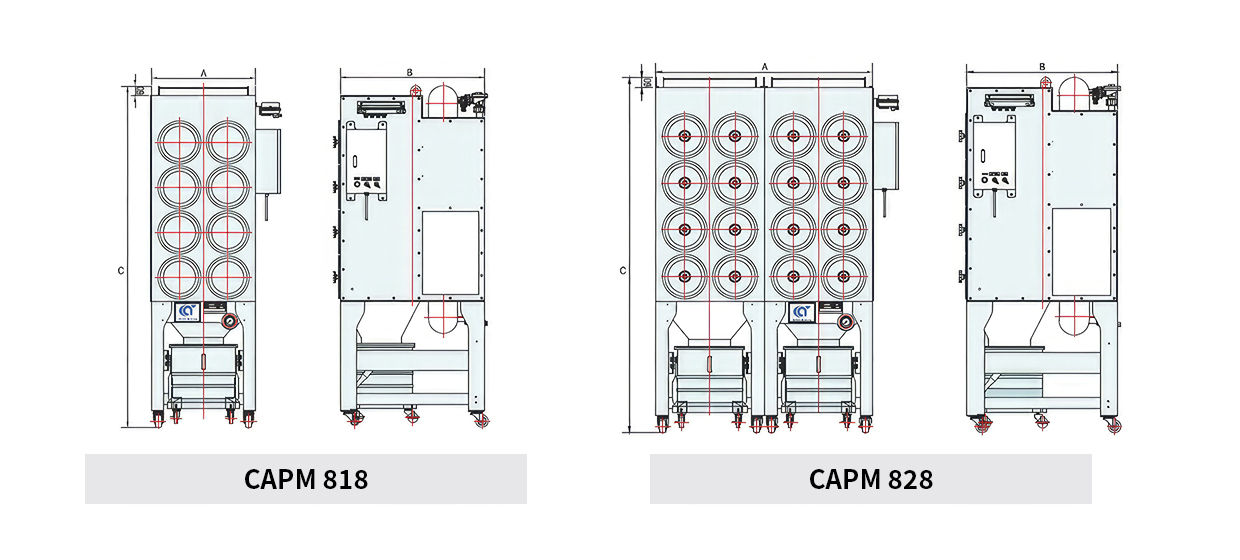

| Model | Dimensions | Filter | ||||

|---|---|---|---|---|---|---|

| Width (A) | Depth (B) | Height (C) | Inlet | Area | Quantity | |

| CAPM-818 | 650 | 900 | 1959 | Ø350 | 48 | 8 |

| CAPM-828 | 1300 | 900 | 1959 | Ø350 x 2 | 96 | 16 |

※ Specifications may change for performance improvement.

Blower Specifications

| Type | Output (Kw) | Air Flow (CMM) | Static Pressure (mmAq) |

|---|---|---|---|

| Portable Type - 1HP | 0.75 | 12 | 230 |

| Portable Type - 2HP | 1.5 | 25 | 230 |

| Portable Type - 3HP | 2.2 | 40 | 230 |

| Portable Type - 5HP | 3.75 | 60 | 230 |

| Portable Type - 7.5HP | 5.5 | 80 | 250 |

| Portable Type - 10HP | 7.5 | 100 | 250 |

| Direct Drive Type | Custom Order | ||

| Belt Drive Type | Custom Order | ||

Key Features

-

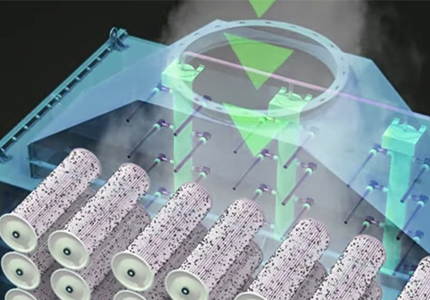

Downward Airflow Dust Collector

- This is a downward airflow dust collector, where the pollutants are sucked from top to bottom, and the filters are mounted horizontally.

- Due to its downward airflow structure, particles collected in the dust bin do not re-scatter due to rising air currents, and particles fallen off the filter surface during air pulsing (cleaning the filter with compressed air) do not reattach to the filter, thus extending the life of the filter.

-

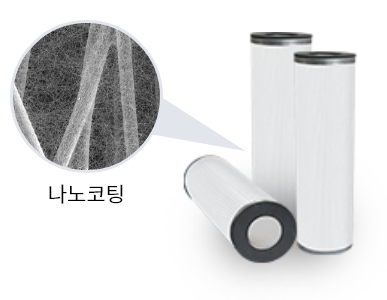

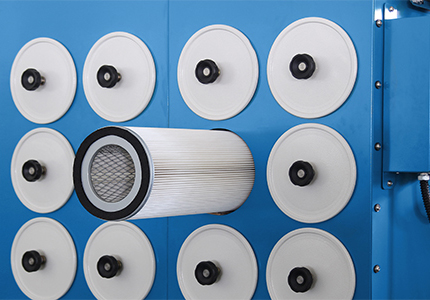

A Dust Collector Equipped with Ultra Nano Filter Developed with Proprietary Patent Technology

- The ultra nano filter coated with nano-fiber on the filter surface is installed.

- With a high filtration efficiency (99.1%@0.3μm), it effectively removes fine dust and fumes.

- It has about twice the lifespan compared to commonly used polyester (Polyester) material filters.

- Developed and produced with our patent technology, making it more affordable than imported filters.

- Standard P&E Filter: Less than 2 years average lifespan

- Membrane Filter: Less than 3 years average lifespan

- Ultra Nano Filter: Less than 4 years average lifespan

-

Air Pulse Jet Cleaning System

- Cleans the filter using the air pulse device (spraying compressed air from the air tank at regular intervals).

- The filter can be cleaned while the dust collector is operating. (24-hour continuous operation possible)

- Particles detached during filter cleaning are collected in the dust bin at the bottom.

- Filters can be individually replaced easily without any special tools by unscrewing the knob.

-

One-Touch Detachable Dust Bin

- The dust bin is designed for easy emptying with a one-touch detachable mechanism.

- It has a window to check the amount of dust collected, and wheels for easy transportation when emptying.

- The distance between the filter and dust bin is extended, reducing the re-scattering of particles due to air pulsing, thus extending the life of the filter.

-

Modular Structure for Easy Maintenance and Sturdy Build

- The capacity can be increased by adding modules.

- The structure is designed with a detachable blower.

- Key components that could be affected by contaminants are externalized to reduce malfunctions.

-

German-made Analog Differential Pressure Gauge

- Equipped with an analog differential pressure gauge from AFRISO, a globally renowned German measurement device manufacturer, ensuring low malfunction rate and precise measurements.

- The differential pressure gauge indicates the degree of filter clogging, informing the user of the filter replacement time.

-

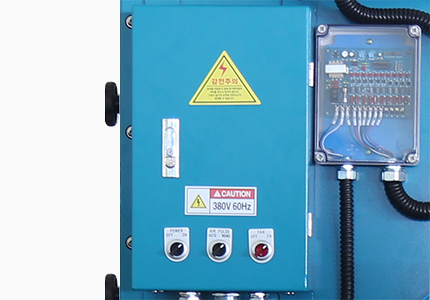

Control Box / Distribution Board

- The switchgear, circuit breaker, and control devices are organized in a separate steel plate box.

- The electrical control devices are not affected by contaminants, extending their lifespan.

- It can be attached and used at a desired location.

Options (Optional)

-

Blower

- The blower can be selected and installed among portable, direct drive, and belt drive types according to the work environment and purpose.

-

Cyclone

- Using a cyclone as a pre-treatment device significantly reduces the amount of dust entering the dust collector, extending the filter's lifespan.

- It removes dust using the principles of centrifugal force and gravitational settling.

- It is more effective for tasks generating large and heavy particles, such as wood and metal dust.

- It is not suitable for small and light fine dust particles.

-

Hopper, Valve

- Changes the dust bin to a funnel-shaped structure for efficient handling of large amounts of dust.

- Dust can be emptied using a rotary valve (automatic control) or a butterfly valve (manual control).

- The extended distance between the filter and dust bin reduces particle re-scattering due to air pulsing, thus extending the filter's lifespan.

-

Flame Arrestor

- Adds a device that extinguishes flames sucked in with the pollutants to prevent fires.

-

Local Switch, Contact Configuration

- Adds a local switch to turn the power ON/OFF.

- It can be attached and used at a desired location.

- The electrical circuit's contacts can be configured to turn ON/OFF simultaneously with other equipment.

-

Flexible Conduit for Wiring

- Covers wires with a flexible conduit to prevent fires due to insulation damage.

-

Customization / Custom Design

- On request, it is possible to change the design or develop new products outside of standard specifications.

- We have the highest level of design responsiveness in the industry.

-

Power Specification Changes

- Options available: 220V/ 380V/ 440V, single-phase/three-phase, 50Hz/60Hz.

Precautions

-

- An air compressor is required because the filter is cleaned using compressed air.

- For dust with explosion risks such as aluminum, titanium, epoxy, etc., please inquire separately.

- If flames are sucked in together with pollutants, a [Flame Arrestor] must be installed.

- It is not suitable for high-temperature gases and dust with a large amount of moisture/oil content.